|

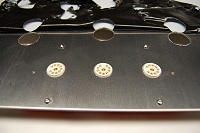

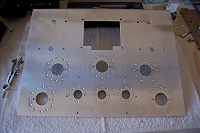

A stock ST-70 unmodified and with original cloth transformers. The output transformers are the first to come out. The power transformer comes out and then all the rest. Tired chassis and after some elbow grease and metal polish. The beginnings of a new layout. The pcb modded slightly for additional clearance to tube sockets. The back of the chassis will bend down at the line. The miniature Honeywell (2TW1-3) switch is for 4/8 ohm taps. The driver board was stuffed with most parts on the bottom side and only the sockets and pots on the top. The chassis has been punched, drilled and cut for all mounts. Time for a side track. I decided I wanted the chassis chromed, so I pulled all the parts off and sent it off to the chrome shop. A few more passes to remove excess wood and then on to the table sander. The metal chassis slides into the wood cabinet. Here are a few competed pics with and without tubes. I want to acknowledge Craig Ostby with

NOSValves.com

|